A.C.E. Prefeeders & Pay-offs

Optimize your wire processor utilization

A.C.E. prefeeders and pay-offs allow you to get the most out of your wire processor. They eliminate wire tangles and spills that occur when your high-speed wire processor starts and stops to finish wires by allowing the wire to be smoothly pulled while still allowing the wire processor to use quick ramp up settings.

A.C.E. prefeeders can pass the wire through a printer at a steady speed to allow continuous wire marking. The prefeeder takes advantage of the time the processor is finishing wires to continue marking wire which allows the processor to pull wire at it’s maximum speed when it begins the pulling phase.

Advanced Concepts Engineering Co. has been making prefeeders for the wire processing industry since 1998.

A.C.E. Prefeeders

Most "wire processors" or "cutters" produce runs of identical wires. A single wire production cycle comprises a pulling step (where the wire length is pulled) and an end-processing step (cut, strip, crimp, etc..). In order to boost production, many wire processors pull wire at fairly high speed (up to 30 FT/second), with sharp acceleration & deceleration, but often with a limited pulling effort.

Due to the end processing stop time, the "average wire drawing rate" from the wire source over a production run is much lower (typically less than 50%) than the top pulling speed from the wire processor.

What does a prefeeder do?

A prefeeder (sometimes also called a de-reeler) draws wire out of an upstream spool, coil or barrel "pay-off", stores it in its "buffer" and allows a downstream "wire processor" pull wire from the buffer, as needed.

Why do I need a prefeeder?

Case #1

Wire pay-off from reels

Due to the reel inertia, starting and stopping a spool/ reel for every single wire is impractical in a high speed production mode.

At the beginning of a multi-wire production run, a prefeeder (with a large enough buffer) buys time to slowly accelerate the reel. During the subsequent production run, the buffer can be filled at the steady average drawing rate while the wire processor draws from the buffer by (high acceleration/ speed) pulses.

Case #2

Wire marking

In many cases, the wire has to be marked at regular intervals, using "on the fly" ink jet or laser markers. Marking systems cannot keep up with the high wire speed and acceleration of many wire processors. It is then necessary to severely reduce the performance and production rate of the wire processors.

A much better alternative is the use of a prefeeder: marking is relocated "upstream of the prefeeder" where the wire drawing speed from the source (spool or barrel) is kept steady and low.

Case #3

Wire pay-off from coils, coni-packs & barrels/drums

In some cases, wire processors can draw wire directly from coils, coni-packs or barrels, without the help of a prefeeder.

However, high acceleration, high speed drawing sometimes create problems such as wire tangles and knots.

It is therefore advantageous to use a prefeeder: the buffer can be filled at the steady average drawing rate while the wire processor draws from the buffer by pulses.

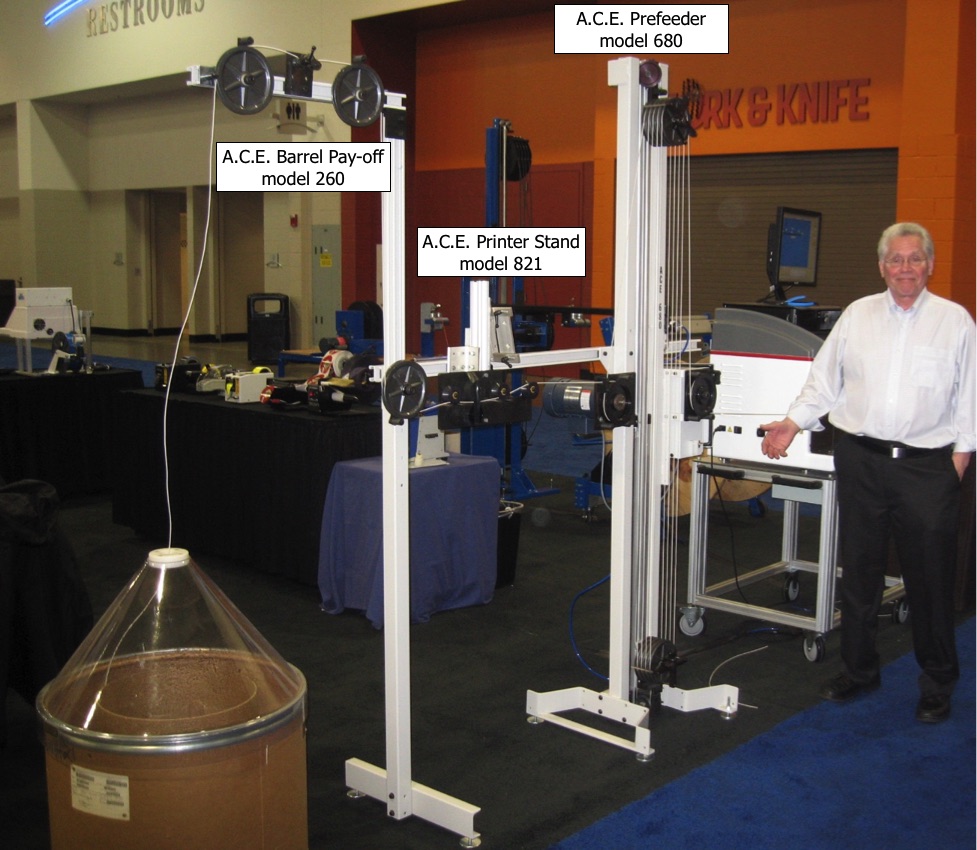

Bruce Eilenfeldt, President of D.T.S, presents an A.C.E. 680 Prefeeder with model 260 Barrel Pay-off and model 821 Ink Jet Printer Stand

A.C.E. Prefeeder Models

All A.C.E. prefeeders feature

- Motorized input capstan and free wheeling output pulley.

- Large, dual dancer wire buffer with settable pneumatic spring.

- Non-contact dancer position sensor array.

- Controls set motor speed depending on dancer position and output wire demand.

- Controls detect error conditions such as wire jam and broken and signal alarm conditions.

- Self-tuning software eliminates any operator adjustment of the speed.

- Hold/Ready signal available to downstream wire processor (NO, NC relay contacts)

- Remote MMI box with "ON" and "Alarm" lights and reset button.

A.C.E. Model 680

Prefeeder

Typically used with aerospace and automotive wire (gauge 24 to 14)

- Input capstan wire speed: 20 ft./sec. maximum.

- Input capstan pulling effort available: 5 to 10 Lb.

- Wire buffer capacity: 50 ft total, 32 ft. useable

- 6” OD capstan and buffer pulleys.

- Footprint: 20 inches X 20 inches approx.

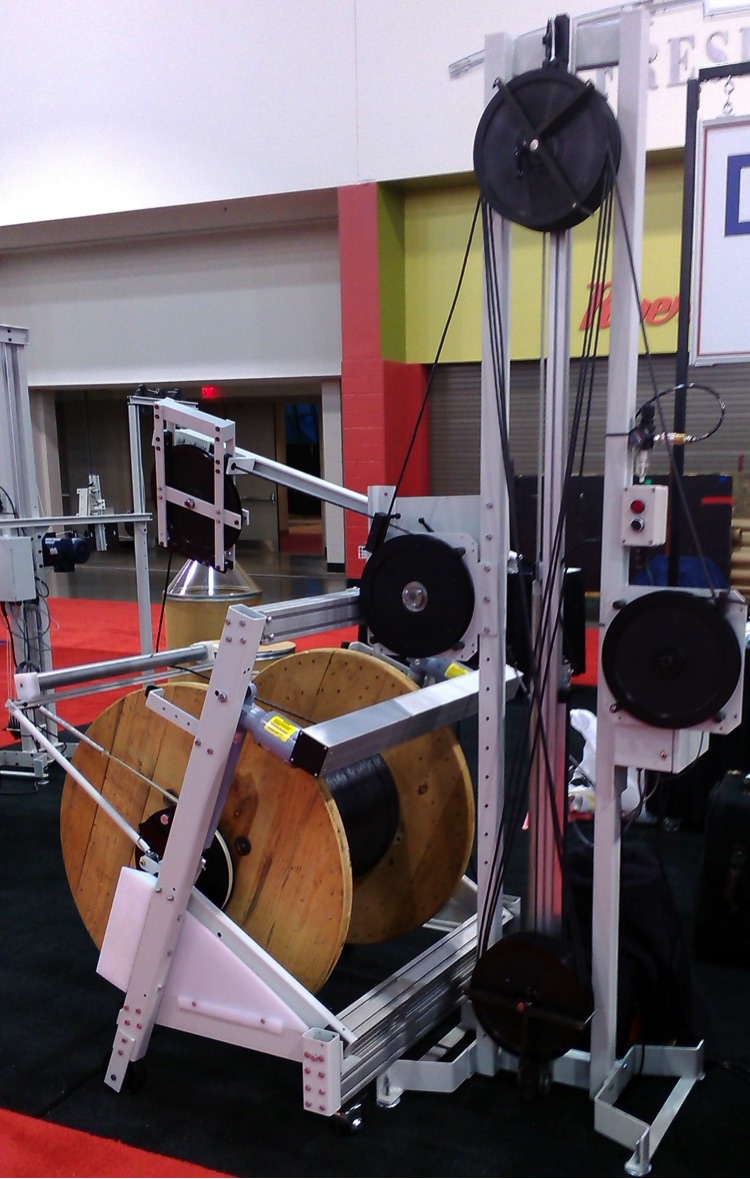

A.C.E. Model 690

Prefeeder

Has larger pulleys and is typically used with flexible cable of OD <1/2"

- Input capstan wire speed: 15 ft./sec. maximum.

- Input capstan pulling effort available: 10 to 20 Lb.

- Wire buffer capacity: 45 ft total, 25 ft. useable

- 12" OD capstan & buffer pulleys

- Footprint: 20 inches X 25 inches approx.

A.C.E. Model 821

Ink Jet Printer Stand

The optional ink jet printer stand allows continues marking along the wire as it runs through our prefeeders.

- Accommodates many ink jet printer commercially available

- Accommodates encoders associated with ink jet printers

- V-grooved pulleys guide the wire under the printer head.

- Precision adjustment of the printer head position

A.C.E. Pay-offs

What does a pay-off do?

A spool pay-off/ de-reeler guides the wire smoothly out of a barrel or off of a spool, reducing wire tangles, spills and jams. By preventing over-rotation when stopping, the wire stays neatly in place on the reel.

A.C.E. 690 Prefeeder with model 250 Large Reel Pay-off

A.C.E. Pay-off Models

A.C.E. Model 240

Medium Reel Pay-off

- Pneumatic lift for reels weighting up to 400 LB

- Reel up to 24" O.D and 18" traverse

- Side loading removable spindle accommodates all reel arbor holes from 5/8" to 3” DIA.

- Self-engaging spool brake controls reel coasting and eliminates subsequent wire spills and jams.

- Sturdy tubular steel frame.

A.C.E. Model 250

Large Reel Pay-off

- Electrical lift for reels weighting up to 1000 lb.

- Reel up to 40” OD, 24” traverse.

- Side loading removable spindle accommodates all reel arbor holes from 1-1/4" to 3" DIA.

- Self-engaging spool brake controls reel coasting and eliminates subsequent wire spills and jams.

- Sturdy tubular steel frame.

A.C.E. Model 260

Barrel / Drum Pay-off

- Redirect wire from top of the drum to ink jet printer stand and then prefeeder

- Accommodates any drum height

- Includes a wire brake to provide minimum necessary drag on wire

- Sturdy tubular steel frame.